Learning how to find alternate suppliers in case of emergency when a natural disaster strikes is essential for all businesses. Disruption due to storms or other similar events can leave companies stranded and without essential supplies to continue their operations. With alternate providers in place, businesses will be able to overcome these events.

Key takeaways:

Once you know how to find an alternate supplier in case of emergency, you’ll be able to overcome the dangers of any natural disaster.

Natural disasters disrupt supply chains and cause serious financial and operational setbacks. When this happens, it can be difficult for suppliers to send products to their stores or warehouses.

To overcome this challenge, many businesses have to use a backup provisioner to get the goods they need. This ensures that any disruptions are minimized and products continue to reach customers. Companies will also reduce their financial losses when they have spare carriers and warehousers to fall back on.

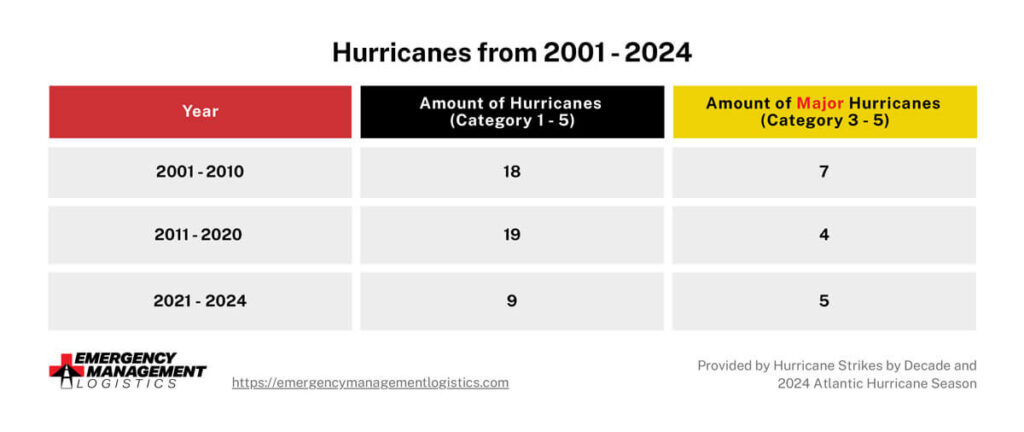

Alternate suppliers are also essential because of the frequency at which natural disasters hit the U.S. every year. For example, consider this data on the amount of hurricanes in the past 22 years.

As the data shows, a total of 46 hurricanes hit the country in a little over two decades, with a total of 16 being major strikes. These are the ones just impacting the United States, so globally numbers are even higher. Businesses in the U.S. Gulf Coast and Atlantic states are most at risk of these powerful storms.

While scientists aren’t sure if the number of hurricanes will increase in the future, they are certain the intensity of these storms will go up. Hurricanes aren’t the only natural disasters that can hurt companies and suppliers. States in the upper Midwest and Great Plains of the country tend to experience severe snow storms.

Earthquakes can also occur, particularly in California, Alaska, and Hawaii. Regardless of where a business is located in the U.S., there’s always the possibility of a natural disaster disrupting the operations of your supplier.

Related: Inventory Protection

Finding new suppliers before a natural disaster will give you the ability to overcome these events. Fortunately, there are a few steps companies can use to find the right one.

These include:

Here at Emergency Management Logistics, we have an extensive logistics network with a variety of small carriers all over the country. We also have resources that can help you import goods in case your supplier is located overseas.

Researching backup suppliers from scratch can be difficult. Fortunately, there are a variety of resources that you can use to connect with new suppliers. We’ve provided a list of the most popular methods businesses use below.

There are online platforms that have numerous suppliers. You can see where they’re located and what products they have to offer. Many of the suppliers on these platforms are located overseas, which means they’ll be out of harms way when a disaster occurs in the United States.

Trade shows are a great opportunity to meet suppliers and see the products they have before entering into a formal business relationship with one. The next time you attend one of these events, take note of the ones that could serve as a backup before a natural disaster occurs.

Finally, you could use referrals and recommendations from individuals in your industry. Trade associations and similar groups could also point you in the direction of new suppliers.

Related: How Weather Affects Transportation

At Emergency Management Logistics, we understand the challenges of maintaining a supply chain in the aftermath of a natural disaster. Our years of experience have equipped countless businesses with the agility and foresight needed to navigate these complex challenges.

The services we provide include:

With these services, your business will be able to recover quickly when disaster strikes. If you’re ready to use our services, then get your quote today. Alternatively, you can also give our team a call at (855) 420-9447 to use our services or ask any questions you might have.