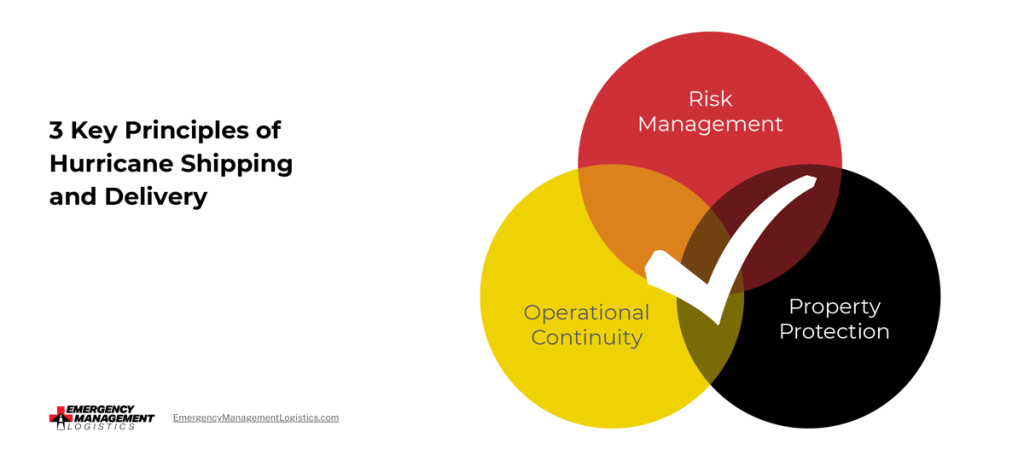

Why do Business Owners, C-suite Leaders, Operations Directors, and Logistics Managers need to understand freight challenges, workarounds, etc. for shipping during a hurricane? Simply put, executives need to understand three key principles: risk management, operational continuity, and property protection.

Hurricane preparedness isn’t just about storm survival; it’s about building long-term supply chain resilience.

Even though I’ll be covering these three key principles in depth and then some, should you have deeper or more specific questions, get the answers you need by calling us at (855) 420-9447.

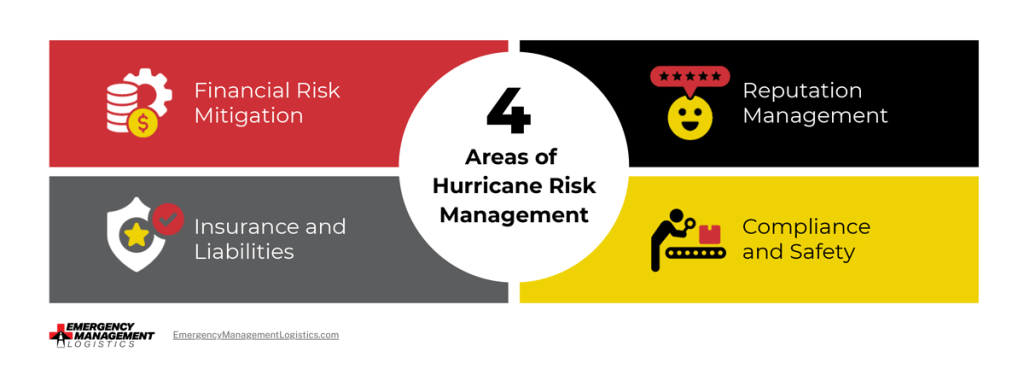

There are four areas of risk management to consider when it comes to a hurricane. But first, let’s clearly define disaster risk management (DRM).

DRM “...aims to avoid, lessen, or transfer the adverse effects of hazards through activities and measures for prevention, mitigation, and preparedness.”

Inter-agency Network for Education in Emergencies (INEE)

Before a hurricane strikes, prepare a financial risk mitigation plan. Having one in place will increase the chances of the company’s survival, while also lessening the devastation that a severe storm can leave in its wake.

Focus on things like building and accessing emergency funds. A good rule of thumb is to have enough capital to cover at least six months of core business expenses.

For most leaders, the thought of keeping six months of expenses on hand feels daunting, especially with today’s operating margins. But businesses that plan ahead with reserves, credit lines, or risk modeling are the ones that stay afloat (no pun intended) when others are forced to close.

You’ll also want to secure other financing in preparation as well. Consider exploring lines of credit or other financing options that can help with recovery costs.

At this stage, you can also use catastrophic risk modeling to project potential financial losses from a Category 3, 4, or 5 hurricane to secure properly sized emergency funds and credit lines to cover worst-case scenarios.

Do you know if your location(s) is/are in a flood zone? Knowing your flood risk is the first step to understanding it from a hurricane. It can also help ensure the company is protected with the proper insurance type(s) as well as the necessary coverage amounts.

It only takes one inch of flood water to create upwards of tens to hundreds of thousands of dollars in property damage, an overwhelming reality for any Operations Manager.

Shipping just prior to, during, or right after a hurricane can bear some serious consequences if not handled properly by your or your emergency management logistics partner. This makes an annual insurance checkup even more important.

The right insurance is more than paperwork; it’s peace of mind that your company won’t drown in out-of-pocket costs.

Do a policy review to check the status of the policy(ies). (I’ll get to hurricane shipping a bit later.) It’s important that there’s no lapse in coverage. Letting a policy expire means a new policy won’t go into effect for at least 30 days, and that’s no way to mitigate the financial risk of your business because of hurricane-inflicted losses.

You should start by confirming that all necessary insurance policies are in place, such as:

Next, it’s time to confirm the coverage amount of each policy and its extensions is correct for your business’ needs. Considering that flood damage, a major source of hurricane-related losses, is often excluded from commercial property insurance, means that preparing now can potentially save tens of thousands of dollars on out-of-pocket expenses.

While being underinsured can lead to significant business interruption losses, you also need to think about liability. If you don’t employ loss-avoidance measures before a hurricane hits, you could face increased stress and anxiety, significant property damage, and even potential injury or death. We help businesses minimize those threats with proactive planning.

Hurricane season is unpredictable, and that unpredictability can cause tensions to rise in business relationships: suppliers, vendors, employees, customers, contractors, prospects, and potentially stockholders too.

In a hurricane, silence can feel like abandonment. Your employees, vendors, and customers need reassurance. Proactive communication with regular updates shows them you’re steady, even when the storm isn’t. Remember, stakeholder trust is fragile during a crisis.

How a business handles logistics pre-, during, and post-hurricane impacts how it’s perceived. Poor communication, along with unmet delivery expectations, and/or visible supply chain breakdowns can erode trust.

Think of proactive and transparent communication as reputation insurance. Best practices include providing regular and consistent automated updates, ensuring shared delay notifications when needed, and even instilling a dedicated crisis-response contact.

Should you experience a carrier issue, know that business relationships will still hold the company accountable. This is why choosing the right Emergency Management Logistic partner is vital. Working with an experienced EML carrier can help mitigate blame and maintain your brand's credibility.

Companies that showcase their resilience, responsiveness, and preparedness are always the ones that come out ahead after a major hurricane. Consider being prepared for natural disasters a part of your competitive advantage.

Organizations that fail to mitigate risk by not establishing a solid emergency preparedness plan and a top-tier hurricane shipping partnership could endure things like negative reviews, public complaints, and possibly lost customers, prospects, contracts, or investors.

Your reputation insurance can also fare well by employing the strength of social media. This can be another avenue of consistent, proactive communication with stakeholders.

Reputation risk isn’t just business-to-business. In this day and age of heightened social media use across the globe, one viral post about shipping delays or a broken supply chain can derail your risk mitigation because it’s quite literally public and immediate. Instead, take advantage of leveraging it by setting the tone and keeping in contact with the audience.

Hurricane logistics are not only an operational concern, though. Reputation management is a public relations strategy and internal teams like marketing, customer support, and logistics should all come together in alignment to inform stakeholders of goings-on while upholding the brand image together.

Communicate early and often. Consistent updates build stakeholder trust, while silence during a hurricane can erode it quickly.

Despite a hurricane, regulations are still in force, be they federal, state, and local. Everything from building codes and occupational safety to transport and environment regulations.

Failing to comply can result in a variety of negative consequences, like:

When your team’s safety and company’s compliance is on the line, the last thing you need is the added burden of fines and lawsuits. Preparing protocols now means you can look after both your people and your organization when the pressure is highest.

Let’s discuss employee safety compliance first. You can protect workers through emergency protocols, evacuation plans, and, if needed, safety shutdown procedures, all of which should be clearly documented and routinely updated.

As for property hazards, hurricanes can cause serious compliance risks, such as:

Without proper inspections and remediation efforts before resuming operations, a business could risk injury claims and/or legal exposure.

What other types of safety and compliance do companies need to know about and prepare to manage effectively? Product and material integrity.

For example, if you deal with perishable goods, working with a committed emergency management logistics provider can help reroute or secure items quickly to prevent exposure and/or spoilage.

Additionally, if sensitive equipment that’s a regulated part of a supply chain is involved in hurricane-related damage, there could be a compliance concern. Being prepared for a natural emergency can help you reclaim your business and rebuild stronger than ever.

Then, formalize these measures into disaster preparedness plans that are reviewed and tested annually.

When a hurricane threatens the supply chain, the question most shippers ask is: how much will this cost me?

There’s no single “hurricane shipping fee.” Costs fluctuate based on:

During hurricane season, rates often rise because of increased risk, restricted capacity, and delays across critical ports and trucking lanes.

The key costs to consider for time-critical shipments include rerouting and detours, port and terminal delays, insurance and protection, and emergency carrier premiums. Let’s discuss each.

In the event of a hurricane, carriers may be forced to bypass closed highways or ports, adding hundreds of miles to a route. More mileage means higher fuel costs and longer delivery windows. In some cases, freight must be delivered to rail or transload yards, introducing added handling charges.

If a storm shuts down a port or intermodal terminal, freight can quickly back up. This leads to congestion surcharges, demurrage for containers left on docks, and detention feeds for delayed trucks.

Businesses often increase cargo coverage or add riders for hurricane season. After a major storm, claims spike, which can drive premiums higher for shippers moving goods through coastal regions.

Organizations may also want to explore specialized hurricane shipping insurance alongside cargo and business interruption coverage.

When only a limited number of carriers operate in a disaster-affected zone, emergency freight moves may result in premium rates. Even with the Federal Motor Carrier Safety Administration (FMCSA) Hours-of-Service exemptions in place for emergency relief, capacity remains scarce and costly.

Managing freight shipping costs before, during, and after a hurricane all comes down to preparation. Shippers that stage inventory inland, pre-book alternate lanes, and work with partners experienced in disaster logistics reduce their exposure to these storm-related surcharges.

By preparing now, companies can reduce unexpected hurricane shipping costs and keep their operations stable through storm season.

If your business needs an actionable plan to control costs this hurricane season, talk to our emergency logistics team at (855) 420-9447. These cost-control measures are also part of broader disaster recovery logistics, structured processes designed to restore shipping operations quickly once storm effects subside.

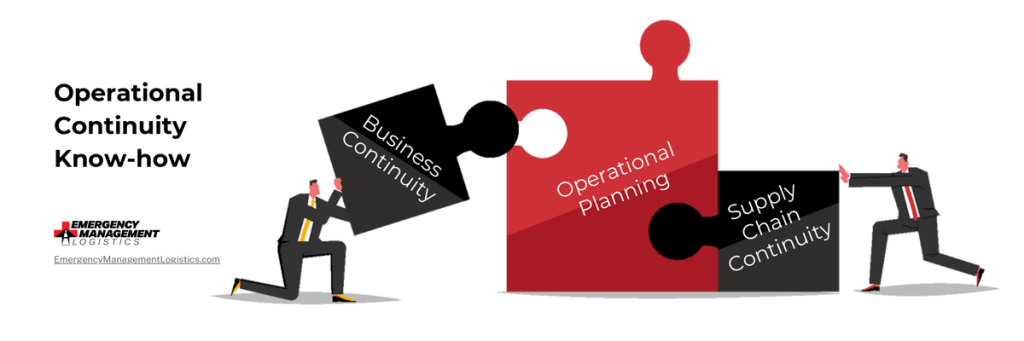

We’ve covered all the areas of risk management to be prepared for as well as shipping cost factors, now let’s focus on continuity. More specifically, operational planning, business continuity, and supply chain continuity.

When a natural disaster occurs, having a proactive, scenario-based plan is a much better position to be in than scrambling to keep operations running. Let’s face it, hurricane season is annual, not hypothetical. Businesses in coastal or storm-prone areas must always consider these violent storms as expected disruptions that require formal planning.

Asking what do you include in the operational part of an emergency management preparedness plan?

If you’ve ever scrambled mid-storm to keep freight moving, you know how costly and chaotic it gets. Our team helps you eliminate that uncertainty with continuity plans tailored to your business.

While it’s great to keep the lights on, business continuity is about much more than that. The cornerstone is about safeguarding people and processes. Starting with employee communication, build a foundation so team members know what’s expected. This can include important things like the employee protections in place, as well as how and where to work remotely, if possible.

Of course, even if operations are paused, communication with customers must continue. Backup systems or service teams should be in place for customer support needs. That includes data protection. Critical files, systems, cloud access, and business records should all have offsite or redundant backups.

In addition, companies should coordinate with local Emergency Operations Centers (EOCs), which direct regional disaster response efforts and provide critical updates that can shape logistics decisions in real time.

Read more on business continuity planning later.

Hurricanes don’t just affect you. They can disrupt an entire region from the port and distribution center to highways and more, rippling across the supply chain. Flexibility in outsourcing and fulfillment options can help with supply chain continuity.

Taken together, these measures reinforce your overall supply chain strength, ensuring that disruptions from hurricanes do not cascade into long-term operational breakdowns.

Don’t rely on a single source or route. It makes you vulnerable. Diversify. Add more safety stock and identify nearby fulfillment support.

Not sure how to diversify your supply chain? Get acquainted with our blog article, “How to Find Alternate Suppliers in Case of Emergency”.

Another way to help reduce supply chain issues is to use partners who can pivot under pressure. As a third-party logistics (3PL) emergency provider, we’re equipped to reroute, store, or expedite goods in real-time when plans change.

One of the biggest questions during hurricane season is whether carriers will continue to move freight. The answer depends on the severity of the storm, local emergency declarations, and the mode of transport.

While some carriers may suspend operations for safety, others will operate under restricted conditions or adjust routes to avoid danger zones.

When transporters work through hurricanes, they know they need to be on top of things like:

Let’s go over each of these in more depth.

The U.S. Coast Guard (USCG) sets port conditions before and during storms. These dictate whether vessels can continue operations, anchor offshore, or halt activity until conditions improve. When ports close, drayage and intermodal trucking schedules are immediately affected.

For instance, during Hurricane Ian in September 2022, the USCG ordered the Port of Tampa Bay closed for three days. This halted all container and bulk vessel activity and disrupted drayage carriers across Florida’s west coast until the port reopened.

The Federal Motor Carrier Safety Administration often issues emergency declarations during major hurricanes. These may provide temporary Hours-of-Service relief for carriers transporting emergency relief goods, but the waivers apply only to specific freight and geographic areas.

State and local governments frequently shut down bridges, tunnels, and major roadways for safety, limiting truck movement into and out of coastal markets. Carriers are forced to reroute freight, which extends delivery times.

These detours highlight why critical infrastructure protection must integrate into any hurricane logistics strategy.

Airlines may ground flights or reroute cargo to airports outside of the storm’s path. This creates temporary backlogs as freight waits for available lift.

The bottom line is that carriers do operate during hurricanes, but in limited, carefully controlled ways. For shippers, this means you must expect detours, delivery delays, and surcharges.

Partnering with carriers that have hurricane response experience, who maintain open lines of communication, helps keep supply chains moving…even when conditions are unpredictable.

As a Business Owner, C-suite Leader, Logistics Director, or Operations Manager, taking ownership of hurricane prep decisions is beyond smart. Protection starts with planning. Get ahead with strategic decision-making, vendor and carrier selection, and asset protection.

Start with smart planning instead of last-minute fixes. For example, weighing short-term costs against long-term losses. This could mean investing in storm-ready infrastructure or emergency freight options.

Why? Because cutting corners can become far more expensive after a hurricane strikes.

Remember to document strategic decisions. Not only does this help with insurance and compliance purposes, but it is also an imperative part of your overarching emergency management preparedness plan. It showcases due diligence and can help mitigate liability as well.

Concerning vendor and carrier providers, it’s important to note that not all partners are equipped, or even willing, to weather the storm. Ask hard questions because standard service to many logistics companies does not equal storm-ready emergency management logistics.

Here’s a jumpstart.

Additionally, build these indispensable relationships before the storm. It’s incredibly more difficult to secure help from new partners in the middle of a crisis.

Don’t underestimate nature. Asset protection is a key pillar of business continuity, so in preparation of a Category 3, 4, or 5 hurricane, focus on:

There are multiple ways a massive storm, causing wind, flooding, power outages, tornadoes, and saltwater corrosion (just to name a few), can destroy materials, products, machinery, and even data. Physically protecting these things by using reinforced storage, raised racks, and sealed containers can literally make or break a business.

Aside from physical protection, transportation needs to be considered as well. Goods could be in transit, and therefore at risk during a hurricane. Use a carrier that can stage shipments strategically or pause transit safely when needed.

Last but not least, establishments matter too. Whether you own or rent, and have a brick-and-mortar store(s), production facility(ies), warehouse(s), or a distribution center(s), confirming the space(s) is/are compliant with local building codes and are severe storm-hardened is another pressing aspect of emergency logistics preparedness. Otherwise, you may need hurricane-rated temporary storage.

Protecting assets during a storm is only one part of the equation. To keep freight moving and customers satisfied, companies need a structured business continuity shipping plan that prepares for disruptions before, during, and after a hurricane.

A hurricane preparedness shipping plan falls under the broader discipline of Business Continuity Management (BCM), which integrates operational preparedness, logistics resilience, and recovery processes into a unified framework.

These plans combine proactive staging, alternative routing, and recovery strategies that minimize downtime and financial losses.

The core elements of a shipping continuity plan include:

Why does having a business continuity plan matter? Companies that have them in place recover faster and spend less on emergency surcharges, compared to businesses without defined COOP measures, who often face longer delays, higher costs, and greater customer dissatisfaction.

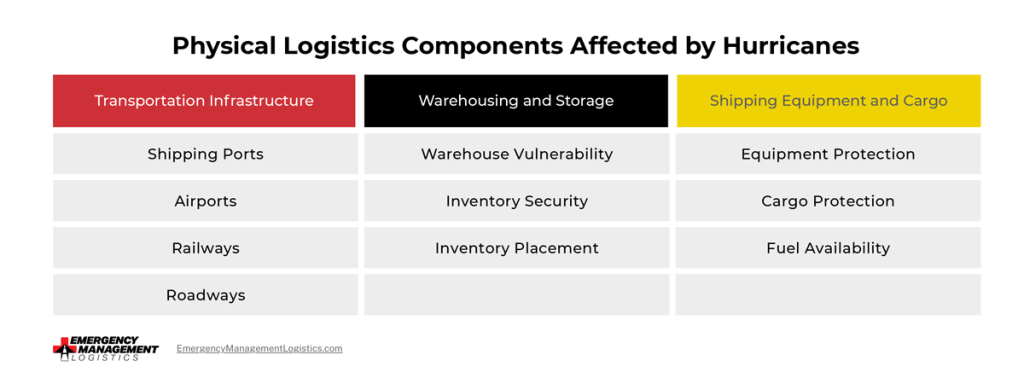

I’ve gone over a lot, so let me provide a quick summary of all the physical logistics components affected by severe storms that are often forgotten in the aftermath of a natural disaster.

If you have goods in transit or need to transport materials or products during a hurricane, it’s important to understand the standard functionalities and capabilities of freight containers. You can use them for shipping, of course, but also for storage.

They’re made to withstand high-winds. As you can imagine, the high seas get mighty windy during the import shipping process. Since they’re typically stacked nine high on cargo vessels, their design and structure are paramount to protecting the merchandise inside.

Made with 14-gauge steel used for the corrugated deck, side walls, front, rear, and roof, a standard freight container stands 20 feet x 8 feet x 8 feet 6 inches (length x width x height). That’s mighty sturdy. But will a shipping container survive a hurricane?

The short answer is not always. If shipping during a hurricane, work only with a logistics carrier who can offer modified, reinforced, and properly secured cargo containers.

You might ask why would I need a hurricane-ready freight container? Here are three situations where being prepared with the right equipment can trailblaze recovery after the storm.

Each of these scenarios demonstrates why post-disaster recovery logistics is just as important as pre-storm planning. Both enable companies to restart operations quickly after catastrophic events.

To easily keep tabs on US port closures, check their statuses. The United States Coast Guard does an excellent job communicating this information. You can also check up on US airport statuses by Flighttrader 24.

After a catastrophic event, get on the road to recovery. Check out “Post-hurricane Recovery for Business and Commerce” for more details.

When traditional carriers are grounded or overwhelmed during a hurricane, emergency logistics providers can fill critical gaps like:

Ensure efficient and reliable emergency management logistics this hurricane season. Protect your operations and ensure OSHA and FEMA compliance by connecting with our emergency logistics experts online today or calling us now at (855) 420-9447.